Chii chinonzi anrobhoti reindasitiri?

"Robhoti"izwi rakakosha rine zvirevo zvakasiyana-siyana zvinochinja-chinja zvikuru. Zvinhu zvakasiyana-siyana zvakabatanidzwa, semichina yehumanoid kana michina mikuru iyo vanhu vanopinda nekuita.

Marobhoti akatanga kunambwa mumitambo yaKarel Chapek mukutanga kwezana ramakore rechi20, ndokuzoratidzwa mumabasa mazhinji, uye zvigadzirwa zvakatumidzwa zita iri zvakaburitswa.

Muchirevo chechinyorwa chino, marobhoti nhasi anoonekwa akasiyana, asi marobhoti eindasitiri akashandiswa mumaindasitiri mazhinji kutsigira hupenyu hwedu.

Pamusoro peiyo mota uye mota zvikamu indasitiri uye muchina uye simbi indasitiri, marobhoti emaindasitiri ave kuwedzera kushandiswa mumaindasitiri akasiyana, kusanganisira semiconductor kugadzira uye logistics.

Kana tikatsanangura marobhoti eindasitiri kubva pamaonero emabasa, tinogona kutaura kuti michina inobatsira kuvandudza kugadzirwa kwemaindasitiri nekuti vanonyanya kuita basa rinorema, basa rinorema, uye basa rinoda kudzokorora chaiko, kwete vanhu.

Nhoroondo yeIndustrial Robhots

MuUnited States, robhoti rekutanga rekutengesa maindasitiri rakazvarwa mukutanga kwema1960.

Yakaunzwa kuJapan, iyo yaive munguva yekukura nekukurumidza muhafu yechipiri ye1960s, zvirongwa zvekugadzira nekutengesa marobhoti mudzimba zvakatanga muma1970s.

Mushure mezvo, nekuda kwekuvhunduka kuviri kwemafuta muna 1973 na1979, mitengo yakakwira uye simba rekudzikisa mitengo yekugadzira rakasimbiswa, izvo zvaizopinda muindasitiri yese.

Muna 1980, marobhoti akatanga kupararira nokukurumidza, uye rinonzi ndiro gore iro marobhoti akatanga kukurumbira.

Chinangwa chekushandiswa kwekutanga kwemarobhoti chaive chekutsiva mabasa anodiwa mukugadzira, asi marobhoti anewo zvakanakira kuenderera mberi kwekushanda uye kudzokorora kudzokorora mashandiro, saka anoshandiswa zvakanyanya nhasi kuvandudza kugadzirwa kwemaindasitiri. Iyo ndima yekushandisa iri kuwedzera kwete chete mukugadzira maitiro asiwo munzvimbo dzakasiyana siyana dzinosanganisira zvekufambisa uye logistics.

Kugadziriswa kwemarobhoti

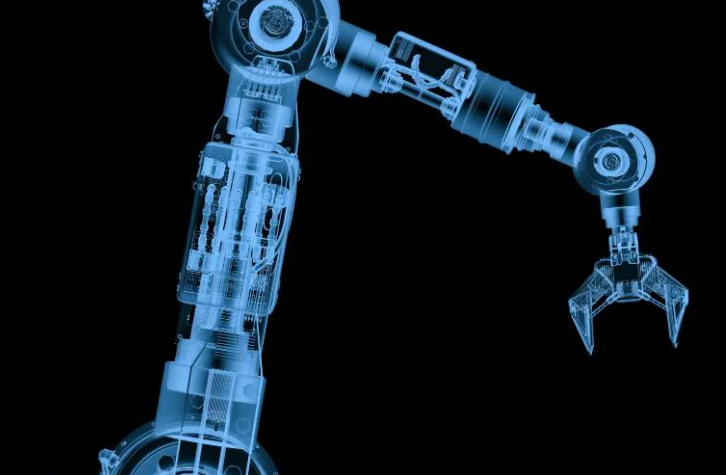

Marobhoti eindasitiri ane mashandiro akafanana neemuviri wemunhu pakuti anotakura basa kwete vanhu.

Semuenzaniso, kana munhu achifambisa ruoko rwake, anotumira mirairo kubva muuropi hwake kuburikidza netsinga dzake uye anofambisa mhasuru dzake dzeruoko kuti afambise ruoko rwake.

Robhoti yeindasitiri ine michina inoshanda seruoko nemhasuru dzayo, uye mutongi anoshanda sehuropi.

Mechanical chikamu

Robhoti inhengo yemagetsi. Iyo robhoti inowanikwa mune dzakasiyana siyana inotakurika uremu uye inogona kushandiswa zvinoenderana nebasa.

Mukuwedzera, iro robhoti rine majoini akawanda (anonzi majoini), ayo akabatanidzwa nezvisungo.

Control unit

Robhoti controller inoenderana nemutongi.

Iyo robhoti controller inoita kuverenga zvinoenderana neyakachengetwa chirongwa uye inopa mirairo kune servo mota zvichibva pane izvi kudzora robhoti.

Iyo robhoti controller yakabatana kune pendant yekudzidzisa senge interface yekutaurirana nevanhu, uye bhokisi rekushanda rakashongedzerwa mabhatani ekutanga nekumisa, switch yekukurumidza, nezvimwe.

Robhoti rakabatana nerobhoti controller kuburikidza netambo yekudzora iyo inotumira simba rekufambisa robhoti uye masaini kubva kune irobhoti controller.

Iyo robhoti uye robhoti controller inobvumira ruoko rune ndangariro kufamba kuti rifambe zvakasununguka zvinoenderana nemirairo, asi ivo zvakare vanobatanidza midziyo yepamhepo zvinoenderana nekushandisa kuita basa chairo.

Zvichienderana nebasa, kune akasiyana marobhoti ekumisikidza maturusi akaungana anonzi end effectors (maturusi), ayo akaiswa pachiteshi chinokwirisa chinonzi mechanical interface pamuromo werobhoti.

Uye zvakare, nekubatanidza iyo inodiwa peripheral zvishandiso, inova robhoti kune yaunoda application.

※ Semuyenzaniso, muarc welding, pfuti yewelding inoshandiswa semagumo ekupedzisira, uye iyo welding magetsi uye mudziyo wekudyisa unoshandiswa pamwe chete nerobhoti semidziyo yekutenderera.

Uye zvakare, masensa anogona kushandiswa seyekuzivikanwa zvikamu zvemarobhoti kuziva nharaunda yakatenderedza. Inoita semeso emunhu (kuona) uye ganda (kubata).

Mashoko echinhu chacho anowanikwa uye anogadziriswa kuburikidza ne sensor, uye kufamba kwebhobhoti kunogona kudzorwa maererano nemamiriro ezvinhu echinhu uchishandisa ruzivo urwu.

Robhoti michina

Kana iyo manipulator yerobhoti yeindasitiri inorongedzerwa nemashini, yakakamurwa kuita mana marudzi.

1 Cartesian Robot

Maoko anofambiswa nemajoini ekushandura, ayo ane zvakanakira kusimba kwepamusoro uye yakakwirira chaiyo. Kune rumwe rutivi, pane kukanganisa kuti kushandiswa kwekushandisa kwechishandiso kwakamanikana maererano nenzvimbo yekubata pasi.

2 Cylindrical Robot

Ruoko rwekutanga runofambiswa nejoint rotary. Zviri nyore kuona huwandu hwekufamba pane rectangular coordinate robot.

3 Polar Robot

Maoko ekutanga neechipiri anofambiswa nejoin rotary. Kubatsira kweiyi nzira ndeyekuti zviri nyore kuve nechokwadi huwandu hwekufamba pane cylindrical coordinate robot. Zvisinei, kuverenga kwechinzvimbo kunowedzera kuoma.

4 Articulated Robot

Robhoti umo maoko ese anofambiswa nemajoini ekutenderera ane yakakura kwazvo yekufamba inoenderana nendege yepasi.

Kunyange zvazvo kuoma kwekushanda kuri kukanganisa, kuoma kwezvinhu zvemagetsi kwakagonesa maitiro akaoma kuti agadziriswe nekumhanya kukuru, achiva iwo makuru emarobhoti emaindasitiri.

Nenzira, marobhoti mazhinji emaindasitiri eiyo articulated robhoti mhando ane matanhatu kutenderera matemo. Izvi zvinodaro nekuti chinzvimbo uye chimiro chinogona kusarudzwa nekupa madhigirii matanhatu erusununguko.

Mune zvimwe zviitiko, zvakaoma kuchengetedza nzvimbo ye6-axis zvichienderana nechimiro chebasa rekushanda. (Somuenzaniso, kana kuputira kunodiwa)

Kuti titsungirire mamiriro ezvinhu aya, takawedzera imwe axis kune yedu 7-axis robhoti lineup uye takawedzera kushivirira kwemafungiro.

Nguva yekutumira: Feb-25-2025