The kurongedzarobhotiinyanzvi yepamberi, yakangwara, uye yakanyatsogadzirwa nemichina yemagetsi, iyo inonyanya kusanganisira hurongwa hwekuongorora hungwaru, kurongedza manipulators, kubata manipulators, stacking systems uye hurongwa hwekutonga, nezvimwewo. Inotsiva maitiro echinyakare ezvinyorwa uye inoziva hukama hwakawanda hwakadai sekutakura kwechigadzirwa, kuronga, kuona, kurongedza, kurodha uye kuburutsa. Iyo ine mabhenefiti ekushanda kwepamusoro uye kushanda chaiko, iyo inogona kunyatso chengetedza manpower, nguva uye zvimwe zvinodhura, uye yakashandiswa zvakanyanya muindasitiri yezvekudya. Classification yekurongedza marobhoti

Kurongedza kwechigadzirwa kunowanzo kuve nemhando dzakawanda. Zvinoenderana nechimiro, zvinhu, uremu uye kuchena zvinodiwa zvechinhu, iyo yekurongedza nzira yakaoma. Parizvino, pane kunyanya anotevera marudzi emarobhoti eiyi nzira yekurongedza:

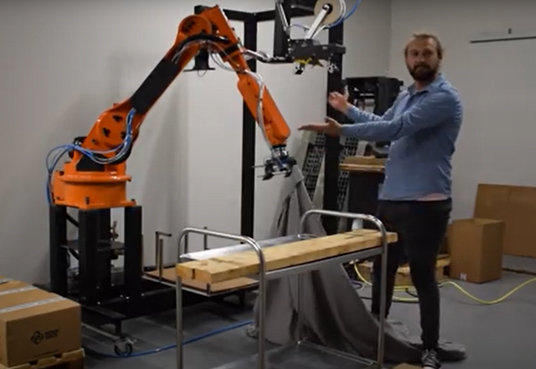

Robhoti rebhegi: Robhoti rebhegi imhando yakagadziriswa inotenderera ine 360-degree inotenderera muviri. Robhoti inopedzisa kutakura, kuvhura bhegi, metering, kuzadza, kusona bhegi uye kurongedza bhegi rekurongedza. Iri irobhoti rekurongedza rakangwara zvakanyanya. Robhoti yetsiva: Zvakafanana nerobhoti rekubhegi, bhokisi resimbi uye girazi rekurongedza midziyo rinowanzopedzwa nerobhoti yakaoma bhokisi. Kune marudzi maviri emakanika uye emhepo ekusveta marudzi ekubata mabhokisi ekurongedza. Inogona kufamba yose. Bata kana adsorb pasuru, wozoitumira kubhokisi rekurongedza kana pallet panzvimbo yakatarwa. Iyo ine basa reiyo otomatiki kutungamira uye kugadzirisa chinzvimbo, uye inogona kuona hapana kurodha uye kutungamira kugadzirisa pasina bhokisi (pallet). Robhoti remhando iyi irobhoti rinenge rakura rine maapplication akawanda. Zvakadai sezvinwiwa, doro, nezvimwe.

Robhoti yekuzadza: Iri irobhoti rinoyera, makapu, matsinha (zvikafu) uye rinozivisa mushure mekunge mudziyo wekurongedza wazadzwa nezvinhu zvemvura. Iine mabasa ekusadya pasina mabhodhoro, hapana kudyisa pasina caps, yakaputsika bhodhoro alarm uye otomatiki kurambwa. Munguva yakapfuura, zvakawanda zvezvinhu zvedu zvemvura zvainyanya kuzadzwa nebasa renzvimbo yeiyi robhoti-iyo manipulator yakaiswa pamutsetse wekugadzira. Ikozvino, robhoti iyi inorongedzerwa zvakananga kuseri kweiyo yekugadzira zvinhu dhizaini kuti ione yayo otomatiki kuzadza. Kuzadza marobhoti akakamurwa kuita akapfava kurongedza uye yakaoma kurongedza. Iyo yakaoma kurongedza (bhodhoro) yekuzadza robhoti inoongororwa pano.

Packaging inotakura robhoti: Iyi mhando yerobhoti muindasitiri yekurongedza inonyanya kureva robhoti rinoshandiswa kurongedza mabhodhoro epurasitiki uye kutakura. Inoshandisa simba uye zvinhu zvakakosha kuona kutakurwa kwemabhodhoro (mabhodhoro asina chinhu), nekukurumidza inoburitsa uye kuronga mabhodhoro ekurongedza mubhodhoro bhodhoro, uye yobva yapa chaiyo (direction, size) simba. Ita kuti muviri webhodhoro upfuure nenzira yeparabola mumhepo kuti usvike pakuzadza workpiece. Robhoti iri rinoshandura chinyakare bhodhoro rekufambisa michina. Inomhanyisa kumhanya kwekufambisa uye inoderedza nzvimbo yekufambisa. Irobhoti rekurongedza rine pfungwa itsva. Inoshandisa aerodynamics uye yakakosha mekiniki zvikamu kuti iwane kushanda kwayo kwekufambisa.

Zvakanakira kurongedza marobhoti

1. Kururama kwekugadzirwa Irobhoti robhoti yakanyatsoiswa pachigadziko chemichina yakasimba, uye mashizha e-multi-axis robot anotenderedzwa ne servo motors uye gears, iyo inovimbisa kuti robot inogona kushanduka uye yakasununguka kusarudza nzvimbo yekushanda mukati mekushanda.

2. Kureruka kwekushanda Iyo sisitimu inodzora robhoti, mechanical gripper uye conveyor bhandi kuburikidza nePLC, uye sisitimu yacho yakashongedzerwa yakakosha touch screen kuratidza ruzivo panguva yekugadzira. Iyo sisitimu inotora yepamusoro-yemunhu-muchina interface, uye vashandisi vanogona kushandura maparamita zviri nyore uye kusarudza zvirongwa pane iyo interface.

3. Kugadziriswa kwekugadzira Robhoti yekubata inoiswa pakati peflange. Inogona kugadzirwa sechishandiso chakamisikidzwa kana kutsiviwa neakasiyana nyanzvi grippers kuburikidza neotomatiki ruoko-kuchinja mudziyo kuti uenderane kune akakosha mabasa. Iyo robhoti inogona kutsiva uye kuisa akasiyana grippers zvinoenderana nezvinodiwa zveiyo chaiyo yekugadzira maitiro kuti isangane nezvinodiwa zvekuchinja kugadzirwa. Iyo robhoti inogona zvakare kubatirana neiyo laser yekuona yekuongorora system kuona rudzi rwechishandiso uye kubatsira robhoti kuwana iyo workpiece.

Zvimiro zvekurongedza marobhoti

1. Kushanda kwakasimba: Kana saizi, vhoriyamu, chimiro uye zviyero zvekunze zvezvigadzirwa zvinogadzirwa nebhizinesi zvachinja, kungoita shanduko kudiki kunodiwa pachiratidziro chekubata, icho chisingazokanganisa kugadzirwa kwakajairika kwebhizinesi. Shanduko yechinyakare mechanical palletizers inonetsa kana kutotadza. 2. Kuvimbika kwepamusoro: Robhoti yekurongedza inogona kugara ichichengetedza mamiriro akafanana panguva yekudzokorora mashandiro, uye hapazovi nekupindira kwekupindirana kwakafanana nekwevanhu, saka kuvimbika kwayo kwekushanda kwakakura.

3. High degree of automation: Kushanda kwerobhoti yekuputira kunovimba nekutonga kwepurogiramu, pasina kubatanidzwa kwevanhu, nehupamhi hwemagetsi, kuchengetedza basa rakawanda.

4. Kururama kwakanaka: Kudzora kwekushanda kwerobhoti yekuputira kwakanyatso, uye kukanganisa kwechinzvimbo chayo kuri pasi peiyo millimeter level, nekururama kwakanaka kwazvo.

5. Kuderera kwesimba rekushandisa: Kazhinji simba re mechanical palletizer rinenge rakapoteredza 26KW, asi simba rerobhoti rekuputira riri pedyo ne5KW, iyo inoderedza zvikuru mari yekushandisa kwevatengi.

6. Yakasiyana-siyana yekushandiswa: Robhoti yekuputira inoshandiswa zvakanyanya. Inogona kupedzisa mashandiro akawanda akadai sekubata, kubata, kurodha uye kuburitsa, uye kurongedza.

7. Kubudirira kwepamusoro: Kushanda kwekushanda kwebhobhoti yekuputira inokurumidza kukurumidza uye hapana nguva yekuvhiringidza, saka kushanda kwayo kunenge kwakakwirira.

8. Diki yetsoka: Robhoti yekurongedza inogona kuiswa munzvimbo yakamanikana uye inogona kushandiswa zvinobudirira, iyo inokodzera kurongeka kwemutsara wekugadzira mufekitori yemutengi uye inogona kusiya nzvimbo yakakura yekuchengetera zvinhu.

Mazuva ano, indasitiri yekurongedza yakapinda zvishoma nezvishoma munguva yeautomation. Seyakanyanya kukwikwidza embodiment ye otomatiki tekinoroji, marobhoti emaindasitiri akakodzera kwazvo kudzokorora, nekukurumidza, kwakaringana uye nengozi maitiro. Iko kushandiswa kwemarobhoti ekurongedza hakugone chete kuderedza mutengo, asi zvakare kuunza kunyatsoita kuchinjika. Kwete kungorongedza marobhoti eindasitiri, makambani mazhinji anosarudza kushandisa akasiyana marudzi emarobhoti eindasitiri nekuda kwekushanduka uye kuvimbika. Mune ramangwana, marobhoti emaindasitiri achatsiva mamwe echinyakare midziyo uye ave imwe yeakakosha masimba ekufambisa mukusimudzira minda yakasiyana.

Nguva yekutumira: Nov-20-2024