1. Kwakabva Marobhoti Eindasitiri Kugadzirwa kwemarobhoti emuindasitiri kunogona kurondwa kumashure muna 1954, George Devol paakanyorera patent yekushandura zvikamu zvinogoneka. Mushure mekubatana naJoseph Engelberger, kambani yekutanga yepasi rose yeUnimation yakavambwa, uye robhoti rekutanga rakaiswa mukushandiswa paGeneral Motors mutsara wekugadzira muna 1961, kunyanya kudhonza zvidimbu kubva mumuchina unofa. Mazhinji ma hydraulically powered universal manipulators (Unimates) akatengeswa mumakore akatevera, achishandiswa kushandura nhengo dzemuviri uye nzvimbo welding. Zvese zviri zviviri zvikumbiro zvakabudirira, zvichiratidza kuti marobhoti anogona kushanda zvakavimbika uye kuvimbisa yakamisikidzwa mhando. Nenguva isipi, mamwe makambani mazhinji akatanga kugadzira nekugadzira marobhoti eindasitiri. Indasitiri inotungamirirwa neunyanzvi yakatanga. Nekudaro, zvakatora makore mazhinji kuti indasitiri iyi iite pundutso zvechokwadi.

2. Stanford Arm: Kubudirira Kukuru muRobotics The groundbreaking "Stanford Arm" yakagadzirwa naVictor Scheinman muna 1969 semufananidzo wepurojekiti yekutsvaga. Aive mudzidzi weinjiniya muDhipatimendi reMechanical Engineering uye akashanda kuStanford Artificial Intelligence Laboratory. Iyo "Stanford Arm" ine 6 madhigirii erusununguko, uye iyo yakazara magetsi manipulator inodzorwa neyakajairwa komputa, mudziyo wedhijitari unonzi PDP-6. Ichi chisiri-anthropomorphic kinematic chimiro chine prism uye mashanu anotenderera majoini, izvo zvinoita kuti zvive nyore kugadzirisa iyo robhoti kinematic equations, nekudaro ichimhanyisa simba rekombuta. Iyo drive module ine DC mota, harmonic drive uye spur gear reducer, potentiometer uye tachometer yenzvimbo uye nekukurumidza mhinduro.Yakazotevera marobhoti dhizaini yakakanganiswa zvakanyanya nemafungiro aScheinman.

3. Kuzvarwa kwerobhoti remaindasitiri rakazara magetsi Muna 1973, ASEA (yava kunzi ABB) yakatanga robhoti rekutanga repasi rose rinodzorwa nemacomputer, rine magetsi akazara eindasitiri IRB-6. Inogona kuita inoenderera mberi nzira yekufamba, inova inodiwa kune arc welding uye kugadzirisa. Zvinonzi dhizaini iyi yakaratidza kuve yakasimba uye robhoti rine hupenyu hwesevhisi hunosvika makore makumi maviri. Mumakore ekuma1970, marobhoti akakurumidza kupararira kune indasitiri yemotokari, kunyanya yewelding uye kurodha nekuburitsa.

4. Revolutionary Design yeSCRA Robots Muna 1978, a Selectively Compliant Assembly Robot (SCAA) yakagadzirwa naHiroshi Makino paYunivhesiti yeYamanashi, Japan. Iyi dhizaini yechina-axis yakaderera-inodhura yakagadziridzwa zvakakwana kune zvinodiwa zvezvikamu zvidiki musangano, sezvo kinematic chimiro chaibvumira kukurumidza uye kunoenderana nekufamba kwemaoko. Flexible magungano masisitimu akavakirwa paSCRA marobhoti ane yakanaka dhizaini dhizaini akakurudzira zvikuru kuvandudzwa kwehuwandu hwemagetsi uye zvigadzirwa zvevatengi pasi rese.

5. Kuvandudzwa kweLightweight uye Parallel Robots Zvinodiwa zvemarobhoti kumhanya uye misa zvakatungamira kune novel kinematic uye kutapurirana dhizaini. Kubva pamazuva ekutanga, kuderedza kuwanda uye inertia yerobhoti chimiro chaive chinangwa chikuru chekutsvaga. Huremu hwe1: 1 kuruoko rwemunhu hwaionekwa seyekupedzisira bhenji. Muna 2006, chinangwa ichi chakazadzikiswa nerobhoti rakareruka kubva kuKUKA. Iyo compact nomwe-dhigirii-ye-rusununguko robhoti ruoko ine epamberi simba rekudzora masimba. Imwe nzira yekuzadzisa chinangwa chehuremu huremu uye chimiro chakaomarara yakaongororwa uye ichiteverwa kubva kuma1980s, inova kugadzirwa kwemichina yemuchina. Michina iyi inobatanidza magumo avo ekupedzisira kumushini base module kuburikidza ne3 kusvika 6 parallel brackets. Aya anonzi maparallel marobhoti akakodzera kwazvo kumhanya kukuru (sekubatisa), kunyatsojeka (sekugadziriswa) kana kubata mitoro yakakwira. Nekudaro, nzvimbo yavo yekushandira idiki pane iyo yakafanana serial kana yakavhurika-loop marobhoti.

6. Marobhoti eCartesian uye maviri-maoko marobhoti Parizvino, marobhoti eCartesian achiri akanyatsokodzera zvikumbiro zvinoda nzvimbo yakawanda yekushanda. Pamusoro pechinyakare dhizaini uchishandisa matatu-dimensional orthogonal dudziro maaxes, Gudel akakurudzira notched barrel furemu chimiro muna 1998. Iyi pfungwa inobvumira imwe kana akawanda maoko erobhoti kuteedzera uye kutenderera mune yakavharwa yekuchinjisa system. Nenzira iyi, nzvimbo yekushanda yerobhoti inogona kuvandudzwa nekumhanya kwakanyanya uye nemazvo. Izvi zvinogona kunyanya kukosha mukugadzira zvinhu uye kugadzira muchina.Kushanda kwakapfava kwemaoko maviri kwakakosha pakuita mabasa egungano akaoma, panguva imwe chete kugadzirwa uye kurodha zvinhu zvikuru. Robhoti rekutanga rinowanikwa pakutengeserana rine maoko maviri rakaunzwa naMotoman muna 2005. Serobhoti rine maoko maviri rinotevedzera masvikiro uye hunyanzvi hweruoko rwemunhu, rinogona kuiswa munzvimbo yakamboshanda vashandi. Nokudaro, mari yezvemari inogona kuderedzwa. Iyo inoratidzira gumi nematatu maaxes ekufamba: 6 muruoko rumwe norumwe, pamwe neakisi imwe yekutenderera kwekutanga.

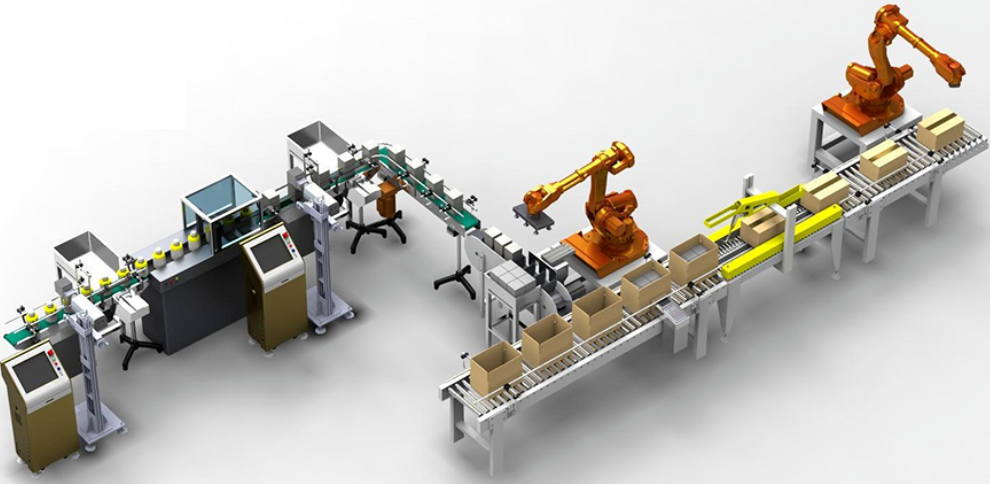

7. Mobile Robots (AGVs) uye Flexible Manufacturing Systems Panguva imwecheteyo, industrial robotics automatic guided vehicles (AGVs) yakabuda. Aya marobhoti enhare anogona kufamba achitenderedza nzvimbo yekushandira kana kushandiswa kurodha-ku-point kurodha michina. Muchirevo che automated flexible kugadzira masisitimu (FMS), AGVs yave chikamu chakakosha chegwara flexibility.Pakutanga, maAGV aivimba nemapuratifomu akagadzirirwa kare, akadai sewaya akaiswa mukati kana magineti, yekufambisa kufamba. Zvichakadaro, maAGV emahara ekufambisa anoshandiswa mukugadzira kukuru uye zvinhu. Kazhinji kufamba kwavo kunobva pane laser scanners, iyo inopa yakarurama 2D mepu yezvino chaiyo zvakatipoteredza zvekuzvimiririra zvigadziro uye zvipingamupinyi zvinodzivisa.Kubva pakutanga, kusanganiswa kweAGVs nemaoko erobhoti kwaifungidzirwa kuti inokwanisa kutakura uye kuburitsa zvishandiso zvemichina. Asi muchokwadi, aya maoko emarobhoti ane hupfumi uye anodhura zvakanakira chete mune zvimwe zviitiko, senge kurodha uye kuburitsa zvishandiso muindasitiri yesemiconductor.

8. Maitiro manomwe makuru ekusimudzira mabhobhoti emabhizimisi Kubva muna 2007, kushanduka kwemabhobhoti emabhizimisi kunogona kuratidzirwa nemaitiro makuru anotevera: 1. Kuderedza mari uye kuvandudzwa kwekushanda - Ivhareji yemutengo wechikwata chebhobhoti yakaderera kusvika ku1 / 3 yemutengo wepakutanga wemabhobhoti akaenzana muna 1990, izvo zvinoreva kuti automation iri kuve yakachipa uye yakachipa panguva imwechete yerobhoti, kukurumidza kwekuita kwerobhoti, panguva imwechete inodhura. kugona, nguva inoreva pakati pekutadza MTBF) yakagadziridzwa zvakanyanya. 2. Kubatanidzwa kwekombiyuta yekombiyuta uye zvikamu zveIT - Tekinoroji yekombiyuta (PC) teknolojia, software yevatengi-grade uye zvikamu zvakagadzirirwa zvakaunzwa neI IT industry zvakagadzirisa zvinobudirira mari yebhobhoti.- Iye zvino, vazhinji vanogadzira vanobatanidza ma-PC-based processors pamwe chete nepurogiramu, kutaurirana uye kuenzanisa mumutongi, uye kushandisa misika yepamusoro yeI IT kuti ichengetedze. 3. Multi-robot collaborative control - Marobhoti akawanda anogona kurongwa uye kurongeka uye kuwiriraniswa munguva chaiyo kuburikidza nemutongi, iyo inobvumira marobhoti kuti ashande zvakanyatsobatana mune imwe nzvimbo yekushanda. 4. Kushandiswa kwakapararira kwemaitiro ekuona - Vision masisitimu ekuzivikanwa kwechinhu, nzvimbo uye kutonga kwehutano zviri kuwedzera kuva chikamu chevatongi verobhoti.5. Networking uye remote control - Marobhoti akabatanidzwa kune network kuburikidza nefieldbus kana Ethernet kuti zvive nani kutonga, kugadzirisa uye kugadzirisa.6. Mienzaniso yemabhizimisi matsva - Zvirongwa zvitsva zvemari zvinobvumira vashandi vekupedzisira kuti vashandise marobhoti kana kuva nekambani yemhizha kana kunyange mupi webhobhoti anoshandisa robot unit, iyo inogona kuderedza njodzi dzekudyara uye kuchengetedza mari.7. Kuzivikanwa kwekudzidziswa uye dzidzo - Kudzidziswa uye kudzidza kwave masevhisi akakosha kune vamwe vashandisi vekupedzisira kuti vaone marobhoti. -Unyanzvi multimedia zvinhu uye makosi akagadzirirwa kudzidzisa mainjiniya uye vashandi kuti vakwanise kuronga zvakanaka, kuronga, kushanda uye kuchengetedza marobhoti zvikamu.

,

Nguva yekutumira: Kubvumbi-15-2025